Well one reason to use a glass print bed is the you get an ultra smooth finish on the "bottom/1st" layer. However with the nature of some plastics such as ABS the thermal properties can cause "warpage" even if you have a heated build chamber and heated print bed. So typically you use an adhesive to better adhere your 3d prints to your print bed in hope to stop any curly before it has a chance to start!

So lets talk about adhesives! I initially was using just blue painters tape, and while it works well any nick or imperfection would sometimes catch upon the printhead, especially if printing at 70 or 100 microns and thus would cause a warp point. Also you wouldn't get that ultra smooth finish with blue painters tape, you'd get the masking tape texture which actually is very nice if you're shooting for that kind of a finish.

Next I went for hairspray, Aqua Net hairspray to be exact. While it did seem to work as well as the painter tape for the basics of ABS and PLA, I found it to be "messy" in that you had to spray apply it, which would result in "over spray" and you'd end up with sticky surroundings eventually, not to mention the urge to cough and cough because of the fumes from the aerosol. Also it would seem to "bead" up on the print bed and thus needed to be smeared via paper towl to get the really good coverage.

I heard of people using ABS Juice, which was a mixture of ABS, possibly scrap portions of previous failed prints, or just clip'd off a portion of filament from the spool you were using and Acetone. I've never attempted this for two reasons, for one you would need ABS Juice for every color that you're printing in, and two what does one do when you print with PLA as its almost impervious to PLA Solvents.

Lastly I heard of using Glue Stick. In fact ultimaker II's now seemed to encourage the use of gluestick, as they included it in the ultimaker's II's box. This is the current adhesive I'm using. It works wonders for both ABS, PLA, and any other filament that I've tried so far, t-glass, wood, etc. (haven't tried Nylon yet). I just put a nice little smear upon the printbed as its heating and then when a print is done I freshen up the smear with a bit more of the glue.

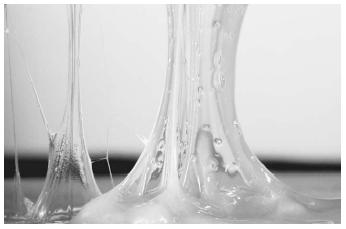

However be it know you might run afoul of the dangers or printing on glass and using adhesives. This pic illustrates an issue I had with some glass plates and thermal pressure/bonding of the glue stick adhesive..

|

| Printed out these lovely little boxes and their covers while letting them cool I heard a few "pops" as they cooled down and were released from the print bed. |

|

| This is what happened when inspecting one of the lids I saw that it had "pop'd" off with a chuck/chip of glass! Strong bond indeed! |

|

| This actually happened on another print as well but with much more catastrophic results. The "pop" was much louder on this one as the print pop'd off and cracked the entire build plate! |

Hope you enjoyed this post and thanks for stopping by!